General FAQ’s

For product specific questions, please visit the product page and click on the FAQ’s tab.

Creative Steel produces all of its components in Salem, Oregon. We take pride in developing product solutions, which is why we strive to keep all manufacturing in-house. We do not produce consumables like hardware, o-rings, and grease zirks. Additionally, we do not apply any coatings, such as zinc or anodizing. These processes are handled by a third-party provider.

Creative Steel offers a lifetime warranty on all polyurethane components and a one year warranty on all other products/parts; valid only to the original purchaser. The warranty period begins from the date the package is affixed with a shipping label. Warranty on each product or part may only be utilized once and does not renew after the replacement is issued. Customers must provide credentials to confirm proof of purchase and pay shipping on all warranty products or parts. It is at Creative Steel’s sole discretion to decide whether the customer’s product or part is covered under warranty.

No reimbursements will be given for delay, labor, mileage, or any other costs in installing or reinstalling parts.

Buyer assumes all risk and liability associated with these products.

At Creative Steel, our objective is to help our customers find a solution regarding any of the products/parts we offer. If you have a claim outside of the warranty period, or if you are not the original purchaser, you will not be dismissed. Please contact us to discuss possible solutions.

The majority of our packages are handled via FedEx. Should you wish to utilize an alternative shipping method or prefer to ship using your own account, please contact us, and we will assist you. (503)-316-1811.

We ship our performance parts to most countries, primarily utilizing FedEx to ensure reliable tracking and secure delivery of your parts. Please be aware that the recipient is responsible for all customs duties, taxes, and brokerage fees levied by the destination country; these charges are not included in our shipping rates and must be paid upon delivery. While domestic orders usually arrive within 2-4 business days, international transit times vary based on location and customs clearance. You will receive an automated tracking email once your order ships to monitor its progress. To ensure security, most international shipments require a signature upon delivery. Finally, please double-check your shipping details at checkout, as address changes cannot be made once an order has been processed for shipment.

Most orders in stock are shipped within 1 to 2 business days.

You will receive an email with tracking information as soon as your order ships.

Depending on the shipping method selected and your location, orders typically arrive within 2 to 4 business days after shipment.

Absolutely! We are fellow veterans ourselves. Give us a call and we can assist you with getting 10% off. (503)-316-1811.

Polyurethane and rubber are two commonly utilized materials in manufacturing. From bushings and mounts to tires and shoes, many different products are produced using these materials. While both materials are chosen for their elasticity in automotive parts, they are not the same.

What Is Polyurethane?

Polyurethane is a synthetic material that was first invented by German chemist Otto Bayer in 1937. Polyurethane is a versatile polymer composed of organic units joined by carbamate (urethane) links, crucial for determining its wide range of flexibility, elasticity, and durability. Formed by reacting polyols with diisocyanates, these materials can be adjusted to be rigid or flexible, covering applications from insulation foams to soft elastomers.

What Is Rubber?

Rubber is divided into two types: natural (organic) and synthetic. Natural rubber is produced from latex harvested from the rubber tree (Hevea brasiliensis), while synthetic rubber is made from various synthesized petroleum derivatives. Synthetic rubber is more widely used than natural rubber. Statistics indicate that approximately two-thirds of the global annual rubber production consists of synthetic rubber, while only one-third is natural rubber.

Benefits of Polyurethane-

Polyurethane typically possesses a longer lifespan compared to rubber, particularly in scenarios where it undergoes frequent stretching or is subjected to stress. Polyurethane can withstand a considerably greater number of cycles of repeated stretching than rubber.

When employed in the manufacturing of automotive parts, polyurethane frequently endures for the complete lifespan of the vehicle. Rubber, while also resilient, is more susceptible to deterioration from continuous stretching or stress.

Simple answer is no. However it will last significantly longer than rubber.

*We still have some of our initial bushings in service today 15+ years later.*

At Creative Steel, we utilize a color and durometer system to simplify the process of identifying the durometer of our polyurethane by its color.

Grey is a 60 durometer shore A

Black is a 72 durometer shore A

Red is a 95 durometer shore A

What is a Durometer?

A durometer is an instrument specifically designed to assess the hardness of various non-metallic substances, such as rubber, vinyl, polyester, leather, nitrile, and neoprene. This device is similar in appearance to a tire pressure gauge, consisting of a needle attached to a spring and a numerical gauge that ranges from 0 to 100.

To evaluate the Shore hardness scale of a particular material, the needle of the durometer attempts to penetrate the surface. The hardness of the material is determined by measuring its resistance to this penetration and any resulting permanent indentation. The pressure exerted during this penetration activates the gauge on the device, providing a numerical reading that falls between 0 and 100.

Based on the numerical reading from the gauge and the size of the durometer needle employed, the resulting value will correspond to specific Shore hardness scales.

What are shore hardness scales?

To grasp the concept of Shore hardness scales, it is crucial to understand that a durometer is not a unit of measurement. Rather, it is a dimensionless metric that indicates the relative hardness of various materials. Thus, the Shore hardness scale serves as a universal reference for comparing these materials.

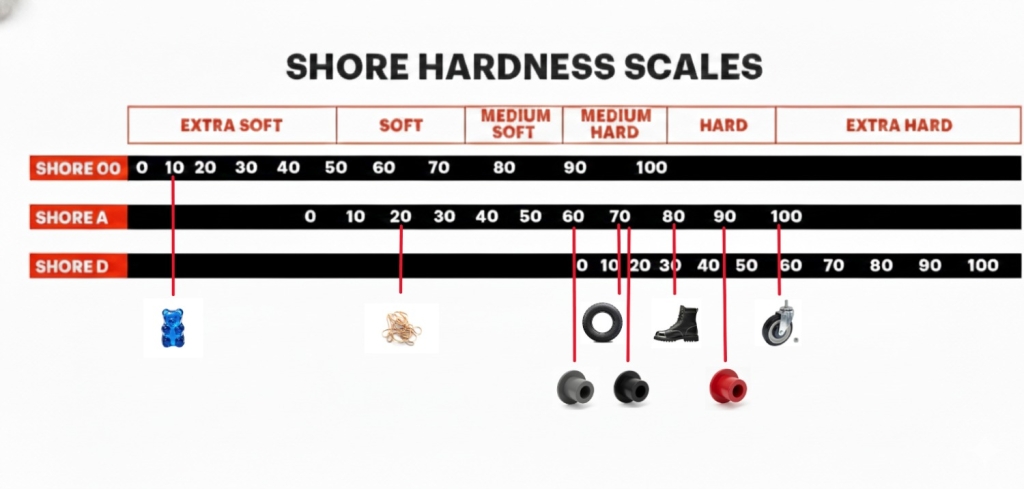

Durometers are divided into three distinct Shore scales. Each scale ranks hardness from 0 to 100:

00 – Evaluates light foams, sponge rubber, and soft gels

A – Measures soft rubber, plastics, and rubber-like elastomers

D – Assesses hard rubber, plastics, and thermoplastics

Each of the three Shore scales utilizes a durometer with a needle of different size. Due to this difference in needle size, certain Shore scales are more effective for measuring specific types of materials.

No matter which Shore scale is used, higher numbers indicate greater resistance to the durometer needle, while lower numbers reflect lesser resistance. Materials that receive lower scores are softer, while those with higher scores are harder.

The image below shows various materials and the Shore hardness scales they correspond to.

Note: Materials can belong to more than one Shore scale. If a material does belong to multiple scales, the measurement values may differ from one Shore type to another.

(Grey) Bushings: Our 60A durometer bushings are only used on parts that require minimal load and lots of NVH isolation. Most of these products will not have a hardness choice.

Street (Black) Bushings: Our 72A durometer bushings are designed for daily drivers to provide a performance boost with minimal impact on comfort. Depending on the product, our street bushings will have a slight increase in NVH that most customers don’t feel.

Race (Red) Bushings: Our 95A durometer bushings are much harder and are intended for track use where performance outweighs the potential for increased NVH. If NVH isn’t a concern, our race bushings are suitable for extreme support without dreaded NVH from solid bushings (delrin or metal).

Some of our bushings are only offered in red due to the OEM bushing already being stiffer than our street bushings.

In the automotive industry, NVH is a term that is widely recognized, describing the quality of noise and vibration within a car. While “Noise” and “Vibration” are measurable, “Harshness” is a subjective evaluation.

- Frequency (The “Speed”): How many times a second the part shakes (Hz). It identifies the source.

- Example: If a vibration happens exactly 15 times per second (15Hz) at 60mph, you can match that speed to the rotation of your tires vs. your driveshaft.

- Amplitude (The “Force”): How far the part moves from its resting position (G-force or m/s²). It identifies the severity.

- Example: A low amplitude is a “tingle” in the steering wheel; a high amplitude is a visible “blurring” of the rearview mirror.

The purpose of an engine mounting system is to minimize NVH to an acceptable level. The ultimate goal is to make the engine’s operation undetectable to both driver and passengers. However, achieving this often requires considerable compromises in managing engine movement and durability. Creative Steel’s “Elimivibe” engine mounts are engineered to provide outstanding NVH isolation capabilities while maintaining optimal engine control.

Squeaking is typically caused by friction between the bushing and the metal housing or sleeve when lubrication is insufficient. To ensure a quiet ride:

Proper Installation: You must liberally grease the inside of the bushing and the contact surface of the inner metal tube during installation.

Use the Right Lubricant: Only use synthetic-based grease (Lithium or Silicone); petroleum-based lubricants can react negatively with polyurethane and wash away more easily. We provide installation grease with our products, and offer a 14oz Polyurethane Grease Tube for long-term maintenance. We highly recommend using our grease as it is specially formulated for our bushings and will not wash away like most other greases. It is thick and tacky.

Maintenance: For rotating parts like grease-able control arm bushings, we recommend re-greasing periodically (roughly every oil change or 5,000 miles) to ensure they remain friction-free and silent. If you start to notice any squeaking from your bushings, regrease immediately to alleviate damage to the bushings.

*If you are experiencing a “clunk” or “knock” rather than a squeak, it often indicates a loose mounting bolt or a failed part rather than a lack of lubrication.*

We offer 3 types of 8.8 carriers- Ford Racing Traction Lok, Eaton Truetrac, and Wavetrack.

Ford Racing Traction Lok- The Ford Racing Traction-Lok is a mechanical, clutch-type limited-slip differential designed to transfer engine power to both rear wheels to maximize traction on the street or track. Unlike an open differential that sends power to the wheel with the least resistance, the Traction-Lok uses heavy internal plate-style clutches made of durable carbon fiber for high-torque applications. When a difference in wheel speed is detected, such as when one wheel slips on a slick surface, the differential’s internal gearing applies axial force to compress these clutch packs, mechanically forcing torque to the wheel with the most grip. This design ensures a smoother transfer of power and improved handling without the harsh engagement found in full locking differentials. https://performanceparts.ford.com/part/M-4204-F318C

(This is the carrier we recommend to 90% of customers. Similar manners to your OEM differential. You will need to use supplied limited slip friction modifier. )

Eaton Truetrac- Is a maintenance-free, helical-gear style limited-slip differential (LSD) designed to maximize wheel traction by automatically transferring torque to the wheel with the best grip. Under normal, high-traction conditions, the Truetrac allows for smooth, independent wheel speeds, acting as an open differential. When one wheel loses traction (e.g., on ice or off-road), the speed difference causes the helical gears to create internal “separation forces”. These forces bind the gears against the differential case, creating a limited-slip effect that forces torque to the wheel with more grip. https://www.eaton.com/us/en-us/skuPage.913A561.html

(We generally do not recommend this carrier for most people. While it is stronger than the Ford Racing unit, we have found that the tolerances in this unit are pretty loose. The rocking of the vehicle when parking or changing direction will be increased. No friction modifier needed.)

Wavetrac- TheWavetrac is a high-performance, gear-based automatic torque-biasing (ATB) limited-slip differential designed and manufactured by Autotech Driveline. It is widely recognized for its patented design that solves the “zero-load” problem common in traditional helical differentials. While traditional gear differentials act like an open diff if one wheel lifts or loses total traction, the Wavetrac’s cam device creates internal load when it senses a speed difference, mechanically forcing torque to the wheel with grip. This ensures constant power delivery during both acceleration and deceleration, providing superior stability without the wear and maintenance of a traditional clutch-style LSD. Constructed from high-strength 9310 alloy steel and requiring no special oil additives, it offers a maintenance-free solution that performs reliably on both the street and the track. https://www.wavetrac.net/collections/ford/products/56-309-186wk

(The Wavetrac is considered the best of the best. These units are really nice however they are expensive. No friction modifier needed.)

*** DO NOT REMOVE PINION NUT, COVER OR ATTEMPT ANY REPAIRS BEFORE CONTACTING CS ***

THIS WILL VOID YOUR WARRANTY IMMEDIATELY

8.8 DIFFERENTIALS HAVE A 1 YEAR WARRANTY FROM DATE OF DELIVERY. THIS DOES NOT INCLUDE AXLE AND PINION SEALS.

ALL WARRANTY WORK MUST BE DONE BY CREATIVE STEEL TO KEEP ORIGINAL WARRANTY

(RETURN SHIPPING IS PAID BY CUSTOMER)

**BREAK IN PROCEDURE MUST BE PERFORMED**

A proper “break-in” of a new 8.8 is critical. If the break-in procedure is not followed almost to the letter, excessive gear whine for the life of the differential is probable. We put these 8.8’s together on the “tight” side of factory tolerances since these tolerances will only loosen with time as the vehicle is driven. The down side of this assembly method is the heat generated by the bearings and gears inside the differential can cause irreparable damage if the break-in procedure is rushed. Heat is the enemy, follow these instructions for your

own good.

Break-in procedure:

Stage 1. After installing the 8.8, drive the vehicle from 0-25mph for 10 minutes, then let the 8.8 cool for 1 hour. Perform this stage of the break-in 5 times.

Stage 2. Drive vehicle from 0-35mph for up to 20 minutes, then let cool for 1 hour. Perform this 5 times. Performing some figure 8’s in an empty parking lot during this stage, is also beneficial.

Stage 3. This is part 1 of the freeway stage. No more than 65mph for 30 minutes, let cool for 1 hour. Perform this stage 5 times.

Stage 4. This stage has no speed restriction, but has a 1 hour limit. Drive for 1 hour, then let it cool for 1 hour. Perform this stage 5 times.

We know this break-in procedure will be torture for most of you guys. We get it. You have waited a long time

for an 8.8 and now we’re being a buzzkill, taking all the fun out of your new toy. The reason for this time is

that we want your 8.8 to be quiet for years to come. That being said; if you absolutely have to smoke the tires

before stage 4 is complete, you have our blessing to slip one in between stage 2 and 3. (6/23)